Induction Hardening

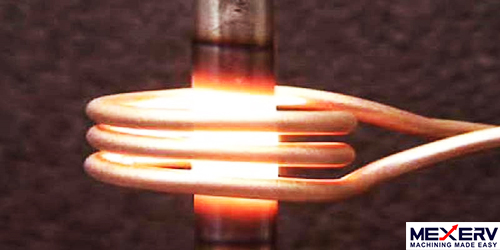

Induction hardening is a surface hardening operation where the job is placed inside a copper coil (that is cooled by water). Now the job is heated above a predetermined temperature by applying an alternating current to the coil. The main advantage of Induction Hardening over flame hardening is that the heating effect can be controlled easily since it is an electrical process.

Benefits of Induction Hardening

- A hard, tough surface with improved fatigue strength is developed with Induction Hardening.

- Since heating and quenching is concentrated only on the surface, heat distortion can be dismissed.

- Localised cooling permits higher surface hardness.

- Exceptionally large components can be treated where other heat treatment methods could be impractical.

- The entire process can be automated.